Disposable Tourniquet

/Product innovation through User-Centred Design

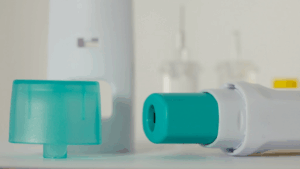

ASEP approached Marble to develop their next generation of disposable tourniquets, with the goal of increasing their market prominence and appeal by expanding their current market offering. The outcome was two new products. Tourni-Stretch a single-patient re-usable tourniquet for extended hospital stays and Tourni-Strip a paper based single-use Tourniquet for emergency situations.

Ethnographic Research

Marble arranged a Usability Workshop in their offices with the design team, phlebotomists, distibutors and key project stakeholders. The team immersed themselves in the product, evaluating current tourniquet options, understanding use modes and preferences, product misconception, mental models and resultant usability issues. The result of the workshop provided valuable input and insight to guide the design direction and specify the product requirements.

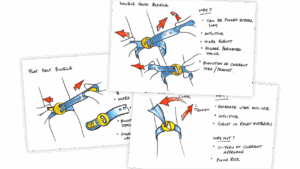

User-Centred Design

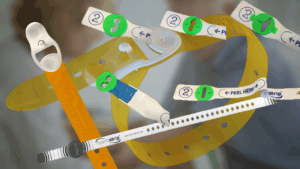

Following the workshop the team developed alternative product concepts to meet the user needs and address the market forces. The design work encompassed not only the product form but the graphic design and potential unique trademarks and brands to guide the users.

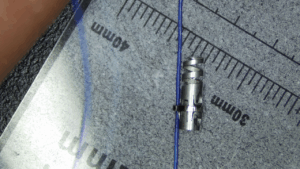

Detailed Design development and Prototyping

Marble's in-house workshop and technician were put to full use to produce rapid prototypes, to enable trial and evaluation of alternative product concepts. The prototypes were evaluated by key product stakeholders in parallel with anthropometric research to understand forces during use and extremes of the user population.

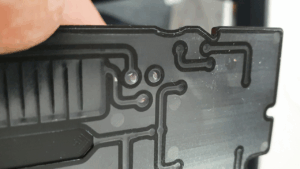

DFM & Supplier Selection

Volume manufacturing, cycle time (via mouldflow analysis), unit cost, stacking and packaging options were considered and compared throughout the development process to ensure concepts could be manufactured and distributed cost effectively. This was vitally important to ASEP due to the price sensitivity of the product. Marble helped ASEP identify toolmakers, moulders and suppliers to manufacture both products, commissioning the tooling and managing inspection and approval of moulded parts.

Material Selection and Optimisation and Testing

A thorough materials evaluation and test programme was undertaken utilising the tensile tester in Marble's lab. This enabled product benchmarking and provided confidence in the material choice both prior to and post tooling release.

Packaging Design

Marble worked with ASEP and their branding agency to develop functional packaging and dispensers for both the Tourni-Stretch and the Tourni-Strip products.